What if there was a simple and accurate tool that let you reduce logistics lead times from warehouse to the stock room, increase the reliability of your delivery service levels, reduce the risk of theft or of products overheating, and shorten transport routes?

e-VSM lets you respond to the operational challenges of your logistics flows, and optimise them!

The management of your logistics flows has a significant impact on operational performance and customer loyalty – be it service, cost, stock, but also environmental impact – so keeping flows efficient and under control is essential.

When your service levels deteriorate or when you decide to try alternative routes, analysing your current performance and knowing what to do can be challenging. For this you need precise, reliable, and representative data that gives you enough visibility and objectivity to make the right decisions.

However, getting detailed data about complex logistics flows, such as multimodal transport and cross-dock operations, is not always easy. It involves various internal stakeholders and subcontractors, which often results in incomplete and out-of-date data.

Most logistics service providers manage data in their own information systems (ERP, WMS, TMS, tracking platforms, etc.), but the data can be scattered, in different formats, and complex to link together and analyse. For example, proofs of delivery are usually hard to collect in full, making the real delivery service level impossible to calculate.

Providers are not always willing to collaborate and communicate details, or do not even have access to those details themselves when sub-contracting.

In some cases, it can be better not to explain that a study is taking place, so that the parties involved in the flow do not temporarily change their behaviours (e.g. in cases of theft).

Finally, there may simply be no appropriate data in existing systems, since they mainly record status or specific events, such as shipments and receipts. Values such as temperatures, handling conditions, or exact route are not typically captured.

Site visits are another way of observing how a delivery process unfolds, but they tend to be costly, and are limited, only reflecting the reality of the time and date observed.

e-VSM is an innovative approach that gives you real-time end-to-end visibility of all your flows and identify ways to optimise them

It relies on the Internet of Things (IoT) technology and the ‘Zero G’ (or 0G) network developed

by Sigfox to automatically track, from end-to-end and almost in real time, all the flows you wish to optimise.

A representative sample of deliveries can be carefully tracked by dedicated trackers collecting data such as location, temperature, and movements the whole length of the journey.

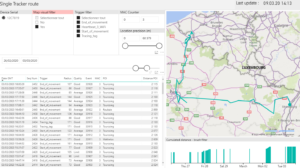

In order to integrate and manage this new data, as well as ‘traditional’ data like shipping and delivery addresses, we developed an application with a processing engine that automatically converts this raw data into meaningful supply chain indicators.

Examples of these indicators include time, dispersion, service level, total distance, number of stops, CO2, temperature thresholds, unexpected shocks, and reliability % of milestones. These indicators are then visualised in an interactive Business Intelligence dashboard, providing both a summary and detailed information. It allows us to accurately describe flows to identify possible sources of under-performance and to build an action plan with the necessary stakeholders.

We use our toolbox to quickly integrate and analyse data

Thanks to this method, Guerlain now has a better understanding of its supply flows. They tracked 100 batches from end-to-end, across several sites and warehouse platforms throughout France and Spain. This made it possible to challenge several aspects of how the flows were organised: production and logistics synchronisation, the synchronisation of flows on platforms, method of transportation (dedicated or grouped, delivery order), and flows run in parallel. In total, a potential lead time reduction of 50 days (-50%) was identified, of which 5 days came from transportation alone.

La Redoute also uses this technology and approach to audit its flows in France, for instance to detect unusual delays when returning uncollected packages.

Other companies use a similar methodology to understand and optimise their intercontinental flows. Michelin tracks thousands of shipments of containers per year and reduced the delivery time on different routes by several days thanks to Safecube – a joint venture start-up between Argon & Co, Michelin, and Sigfox, specialised in flow monitoring and IoT. This method could be used to analyse temperature, either for focusing on this issue or in addition to lead times.

Benefits go beyond the scope of shipments or tracked flows. Simply visualising a part of your flows can help streamline the chain, empower stakeholders, and discourage certain behaviours. Potential thieves are also less tempted to steal if ‘package traps’ are introduced.

This type of temporary tracking can be a first step to operational tracking. Besides gathering data for a given flow, this method can be implemented to trial new tracking concepts and validate its value. It can then be turned permanent on some key flows.

This pragmatic method stands out from existing methods thanks to:

- its short implementation time (the only requirement is to order the trackers beforehand)

- its accurate, representative, and field-based data

- its automatic and end-to-end data capture (the only thing you have to do is to insert and collect the trackers)

- its ability to be deployed on a large or small scale, depending on the company’s needs

- its adaptability to many known logistics challenges, including tackling some at the same time

Do not hesitate to contact us if you have any questions. e-VSM can help shed light on and optimise your logistics flows, starting now!