The requirement to make changes in retail supply chain structures is critical to customer experience and the associated success of retail organisations. Doing nothing is not an option.

Whilst recognising that most retailers have taken actions to address some of the short-term challenges, only a few have truly set the foundations for their future supply chains. Building a customer centric supply chain with the capabilities to support omnichannel retail requires a strategic roadmap of building blocks that iteratively increase customer experience alongside supply chain agility and efficiency.

The first step is a strategic review.

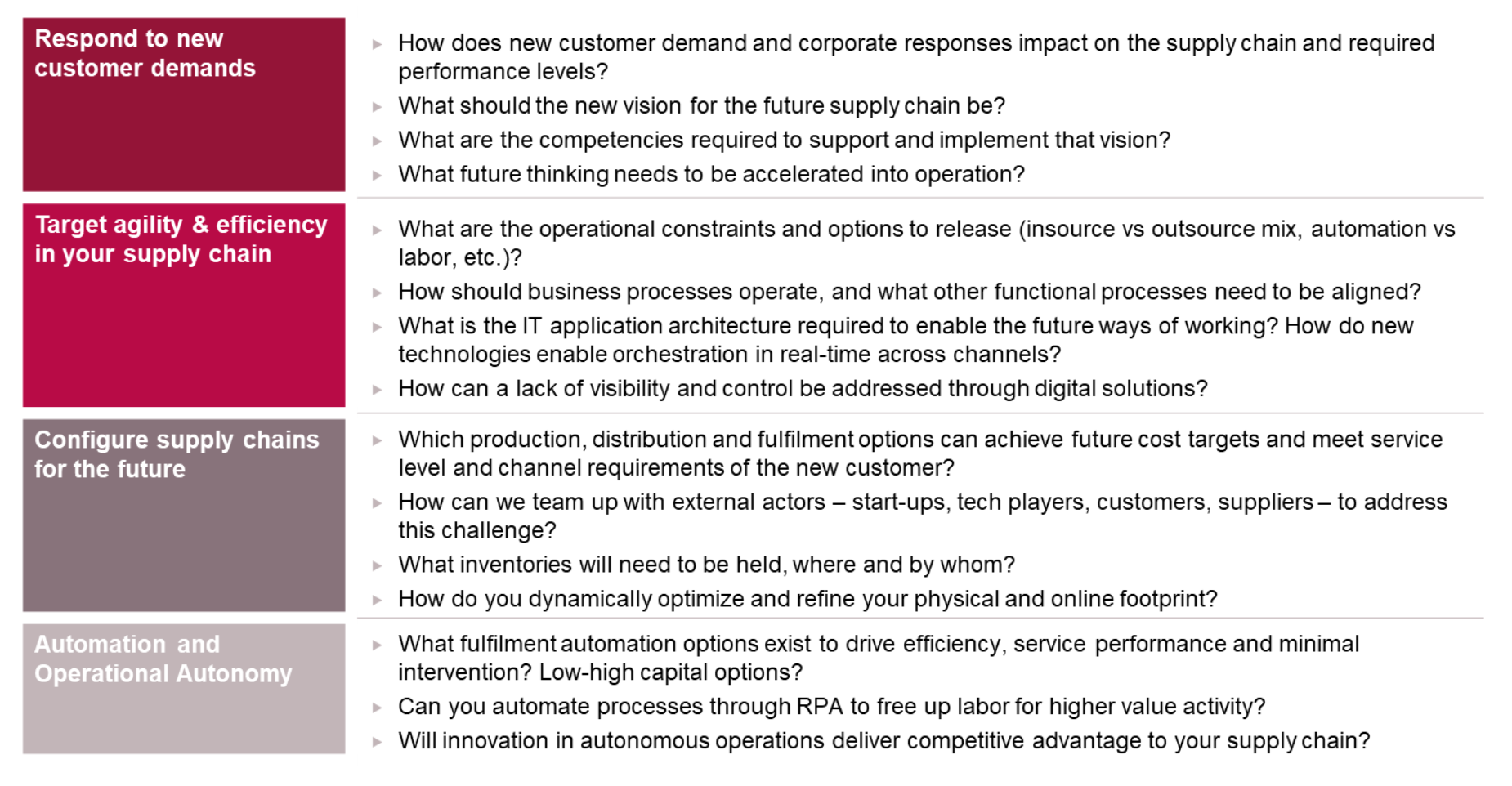

We have posed a few questions below that help to define the key principles that should underpin a future fit supply chain.

If you are interested in learning what our strategic approach is for future fit supply chains, then read on.

Continuing our series covering the rise of E-commerce and following on from our distribution network design webinar, we are now discussing the theme of responding to the rise of E-commerce through reconfiguration of your supply chain.

Through COVID-19 lockdowns, when stores were closed many retailers managed to stand up incremental fulfilment capability across their networks, this served a few purposes:

1) increase capacity to meet online customer demand,

2) utilise and retain staff,

3) maintain availability whilst inbound supply was challenged,

4) consume inventory from stores that otherwise would have been closed, avoiding a working capital issue.

These are all fantastic outcomes as a result of agility and resilience in the face of adversity. The big question now is how to sustainably embed a customer centric and efficient fulfilment capability.

The rise of E-commerce has led most retailers and their associated supply chains to consider the setup of their physical network to get the right balance between speed, flexibility and efficiency. The customer has been at the centre of this transformation with the focus on enhancing optionality, choice, and rapid fulfilment.

It has been interesting to see the different approaches being taken by retailers across the globe. Solutions range from store based fulfilment, micro fulfilment centres, large scale centralised fulfilment centres and various hybrid models.

The solutions tend to be driven by two macro factors; speed vs efficiency and the existing network configuration. Fulfilment is generally faster when retailers can use a network of assets close to the customer demand, leveraging existing stores and distribution facilities. Fulfilment is generally more efficient from a purpose built fulfilment centre (micro of centralised) where the picking & pack cost efficiencies offset the freight cost differential.

However, whilst network configuration is important in determining the customer experience and cost to serve, without inventory and order management capability the expected outcomes will not materialise – in fact, the opposite could play out. Imagine a customer’s order contains a number of different SKUs, but the order can only be completed from multiple fulfilment locations because none of them had the full range or availability to meet the entire order – this leads to multiple picks, packs & deliveries to our customer, which is not a great experience as well as unnecessarily expensive for the retailer.

Or, imagine having a super-efficient centralised fulfilment centre, but not having availability in that location but you do across the wider network – this leads to a lost sale and likely a lost customer.

Inventory optimisation has long been at the heart of solid supply chains. To support the rise of E-commerce inventory management must step up and enable the required balance between speed, flexibility and efficiency.

Without having the right levels of inventory available that customer order can not be fulfilled in the optimal way. Inventory strategies, policies, processes, and systems need to be updated to support the new E-commerce supply chain across suppliers, distribution centres, fulfilment centres, micro-fulfilment centres, stores, 3PL providers and customers. This does not necessarily mean there is a need to hold more inventory, in fact, distributed order management should minimise the risk of stock obsolescence.

Visibility of inventory availability is also paramount for both the retailer and the customer – for the retailer being able to see all inventory in the network enables the right decisions to be made – for the customer, knowing the level and location of inventory within the retailer’s network manages awareness and expectations. Inventory status needs to be real time, with the entire network inventory holding, inventory in-transit, on-order or part of a supplier’s extended range able to be considered within the product availability and order allocation calculations.

Order management is crucial to ongoing success with the rise of E-commerce. The ability to leverage the real-time network inventory position to consider the optimal fulfilment for each customer order holistically whilst balancing workload across the facilities becomes a competitive advantage.

The ability to orchestrate distributed order management using advanced optimisation strategies can ensure sustainable delivery of your customer service levels consistently.

We will be back with the next instalment in this rise of E-commerce series in September with ‘agility & efficiency in your supply chain’. In the meantime, please reach out to us if you want to know more about inventory optimisation and order management.