The EIPM conference took place in March 2021. It was organised in partnership with Argon & Co and it brought together more than 600 participants from all over the world. One of the streams of the conference was dedicated to Tackling Risks.

We had interviews and a roundtable discussion led by Hervé Legenvre, EIPM, that brought together:

Fabrice Thomas – Agilent – Vice President Global Supply Chain

Ysaku Kuhara – Japan Airlines – Risk Management Director

Karl Breidenbach – Infineon – Senior Director Procurement Production Partners

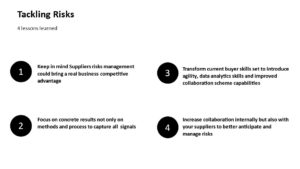

The present article discusses how to go beyond the classical risk management approach and some lessons learnt during the Covid-19 crisis we have been facing.

Tackling Risks: Mixing short and long-term to support business performance

In the volatile environment procurement is now used to sailing in, risk management is at the heart of the performance. This creates a lot of opportunities to leapfrog competitors and to reinforce the relationships with one’s supplier’ portfolio. It is a battle against time. Identifying risks and implementing the countermeasures at the proper time is not a given.

Setting up strong foundations

Firefighting or long-term views are not the unique options for suppliers’ risk management. As options are multiplying and time to act is shortened, companies must reinforce their interactions between all parties, relying on 4 major pillars: skills, technology, cooperation and agility.

Skills are more critical than ever. They encompass a deep understanding of the business needs, the internal stakeholders’ ecosystem, the suppliers’ landscape, behaviours and strategy, and the macro trends of their industry. These are additional ones which will make the difference in terms of performance. Suppliers should not be forgotten. They also need to increase their ability to share with their customer their vision in an open book approach. People behaviour is part of the game changer and new jobs are emerging from the crisis.

“Develop advanced skills for the whole ecosystem”

Technology is becoming one of the key enablers of the risk management process. Risks are more and more diverse and the signal which helps anticipate them, is clearly diffused and coming from different directions; from the inside of the company through suppliers, and from the whole world (macro-economic trends, weather conditions, politics, regulations….). Technology is not taking over human decisions but is strengthening the capability of the teams to take the right decisions at the right time with the appropriate level of effort.

“Put data and analysis in the critical path for risks management”

Cooperation is not an old fashion word. Even if skills and technology are now required to tackle risks, we shall not forget that it is a human-based decision process. The crisis has shown that, more than ever, regular contacts should be set and managed at all levels on both supplier and procurement sides.

“Keep the line open with suppliers and stakeholders”

Most companies were not able to identify the Covid-19 risks, some risk trees were missing pandemics! Do not try to blame anyone but change the way you work and consider agility as a key strength. Procurement professionals must challenge their own beliefs and practices.

“Adapt and focus on results”

Making it happen!

Foundations are set and agility is now a given. We now need to transform risk management to concrete action plans. Keep in mind the final performance could be improved even in a volatile environment.

We all know category strategies drive procurement activities and suppliers’ portfolio. They are built on a set of hypotheses where accuracy is now limited in time. Opportunities in the crisis moment are captured if the team identifies them efficiently. It is time to change category strategies timelines and to adapt them to the overall background.

“Revisit your categroy approach actively to capture business opportunities”

Tackling risks requires finding the right degree of autonomy and unleashing the initiative and the right to speak out loud. Stronger performers have revisited their governance to act quickly but also to manage the interaction between all these local decisions. Resources with less pressure should be refocused to areas where pressure is strong, and resources limited. Personal skills and business understanding are required to help resources on-boarding when needed.

“Balance workload where needed”

After the time of remote discussion and decisions, procurement should come back to the shop floor to see concrete measures set by suppliers, to identify new ones, and also to make the collaboration stronger. They should transform crisis processes to standard agile processes and keep filling the improvement ideas pipeline.

“Explore new ideas”

To conclude, there is not so much new for procurement and suppliers collaboration. We all were taught risk is part of the Category Management processes, culture and organisation. Now it is ‘for real’ and Management will no more wait for answers to their questions, they are expecting anticipation and initiatives.

Si vous ne visualisez pas cette vidéo correctement cliquez ici