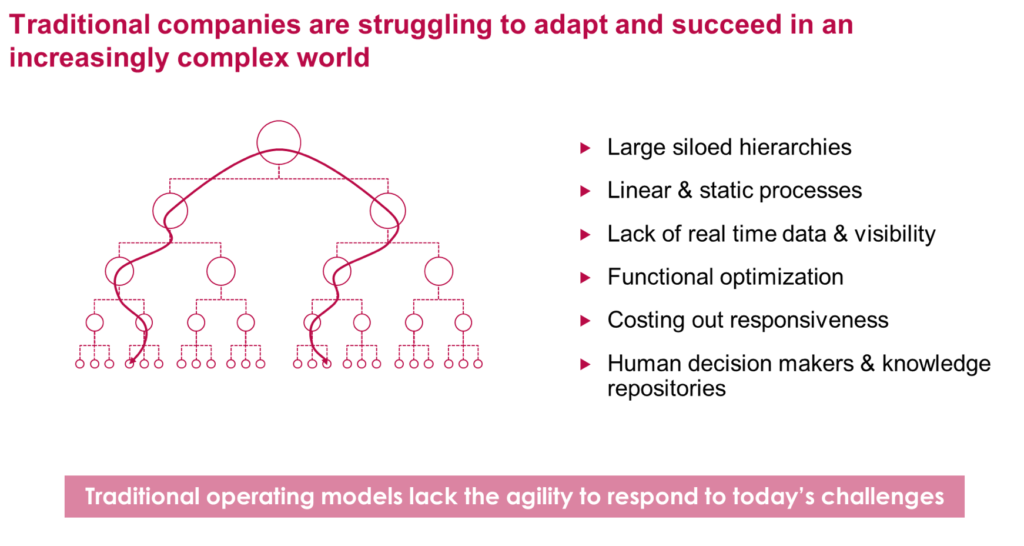

In recent years we have seen traditional companies struggle to meet increasingly dynamic customer needs and to be competitive in a more disruptive and rapidly changing market. These difficulties have become more evident through the COVID-19 pandemic, especially in retail markets where pure play digital retailers dominate.

We see this struggle in-part due to the inflexibility of traditional operating models, which have historically been suited to pursuing lower operating costs as their primary objective. The characteristics of which are largely defined by constraints and operating siloes – see the chart below.

Operational agility is the missing key ingredient to removing this inflexibility, and is increasingly becoming the new objective of most global and national supply chains.

If we view enterprise operating agility as the key to being commercially successful in a more complex and dynamic world, what does this mean for the future operating model?

We believe it means an operating model that is managed in real time, is more accurate and dynamic in its ability to drive efficiency and speed of decision making; one that is scalable beyond the constraints of today’s functional data siloes and human constraints.

This transformation is an evolution, and it starts with a digital foundation as a first step.

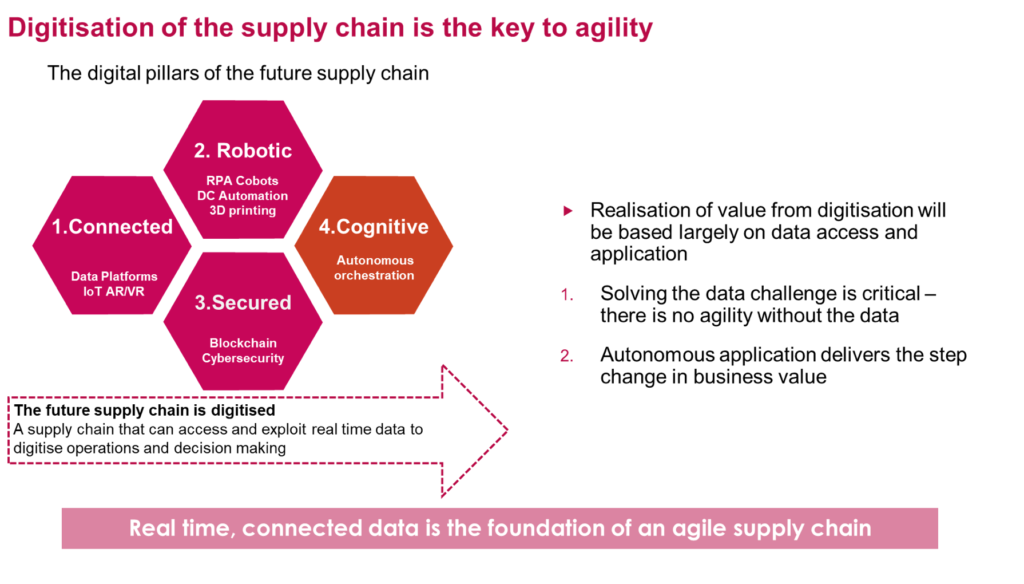

We see four digital pillars in a future supply chain, several of which are rapidly accelerating in the market.

A future supply chain will be:

- Connected – digitising the end-to-end value chain through real time, harmonised and connected data

- Robotic – physical automation of operations & administrative processes to drive efficiency and responsiveness (DC automation, mobile robots and RPA)

- Secured – more secure and transparent transactions in the value chain, and a focus on cyber security to protect our digital assets through technologies like blockchain

- Cognitive – intelligent supply chains that can exploit real time data to inform, control and automate decision-making at scale

The two main key points to realising value from digitisation are, solving the data challenges of today, and developing the ability to apply insights to decision-making at scale.

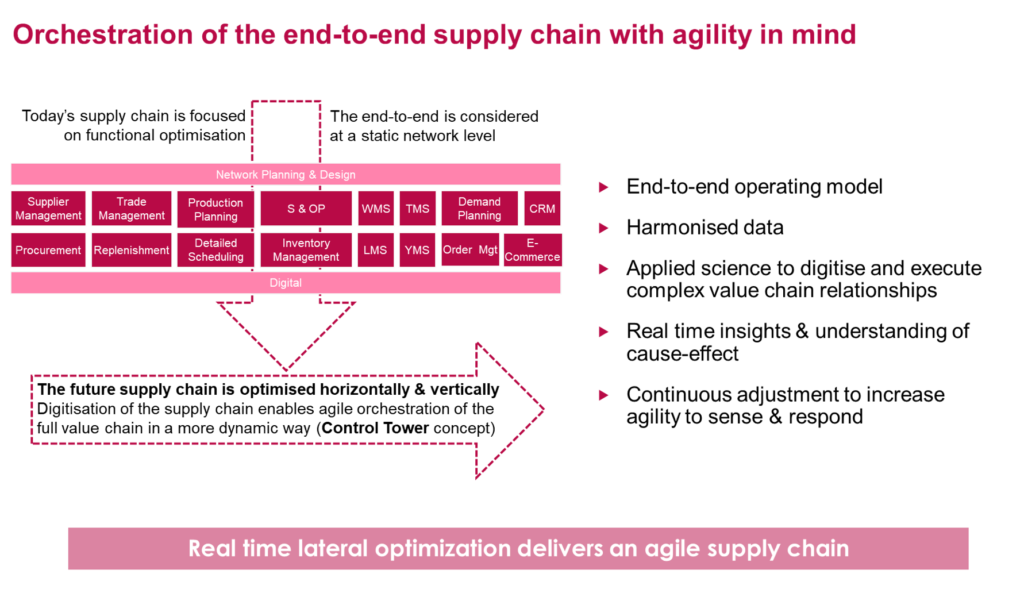

The second step in the journey to enterprise agility is bridging the current gap between vertical and horizontal orchestration of the end-to-end supply chain.

In today’s supply chains, the end-to-end consideration is normally made at a macro and aggregated level over a fixed cycle, which we believe leads to a bias for functional decision making at the operational level. It is exceptionally difficult to break functional siloes with the way current functional application architectures are structured.

However, with the development and application of advanced data management and applied science capabilities to supply chain; operational siloes can become increasingly visible and more connected with real-time awareness of cause and effect along the value chain.

Now, not only can you create a digital and dynamic model of your supply chain, but you can also start to optimise laterally through these new capabilities, which is fundamental to agility and operational responsiveness in conjunction with commercial value awareness. Removing the trade-offs of resourcing and time to address issues such as loss of revenue, waste, excess costs and poor customer experiences, to name a few.

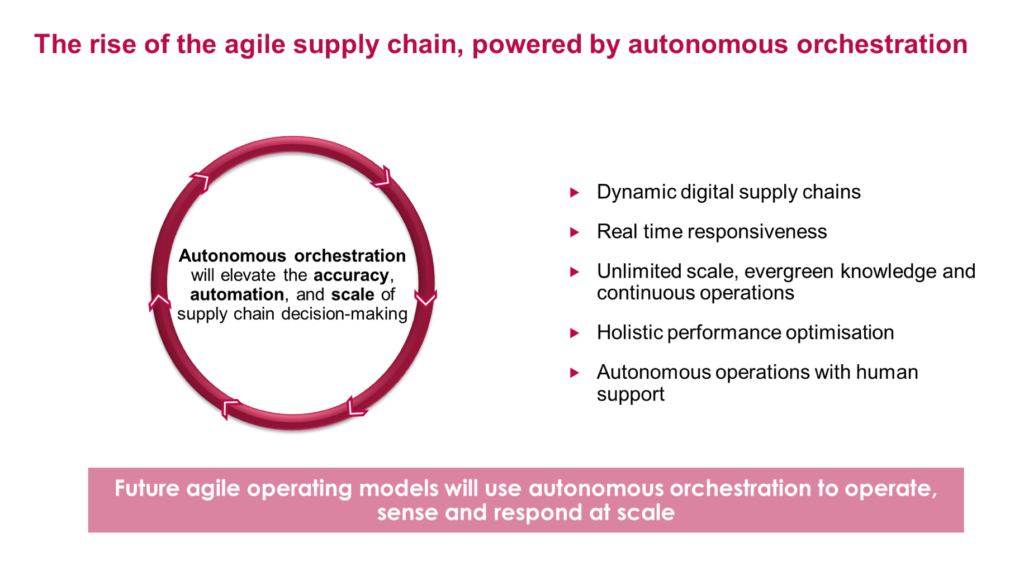

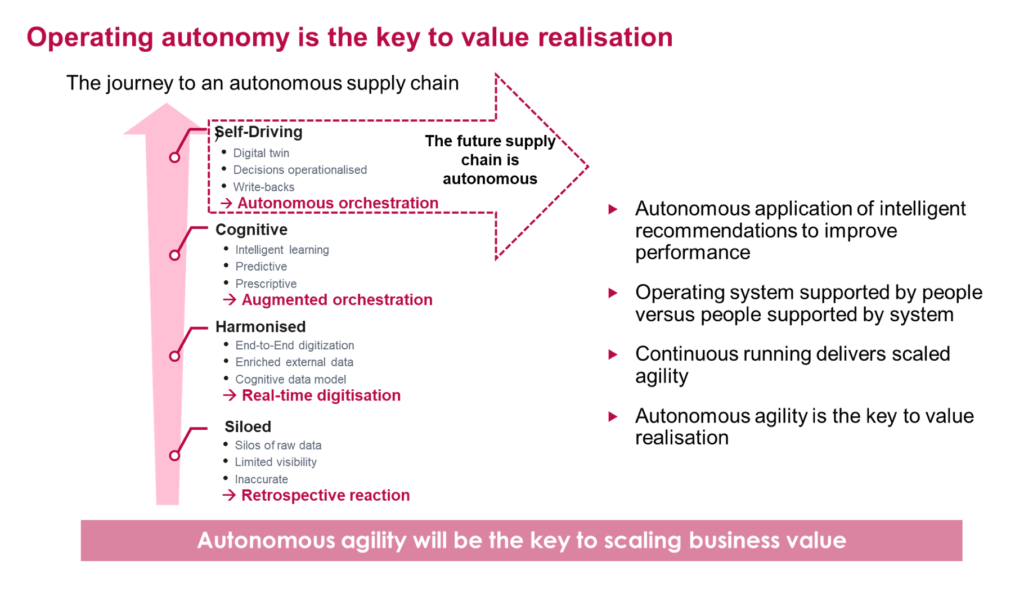

The final stage in the rise of an agile supply chain and the key to value realisation of agility at scale, is the autonomous application of systemic and intelligent decision-making over the enterprise.

The previous steps have outlined the evolution to this point, moving from today’s siloes – reactively responding to the past and being limited by a changing future, through to real-time digitisation – with enriched data and an ability to see the end-to-end value chain, intelligent lateral orchestration – with intelligent learning and a prescriptive capability to forward orchestrate and to ultimately, autonomous orchestration – an autonomous scaling of operational decision making and self-driving actioning.

To be clear, this would not be an operational model without people; it is simply a transition of the role of human users to a higher-level functioning. In fact, although autonomous orchestration focuses on processes and tools, it is there to make interactions between individuals more meaningful, break down siloes, and accelerate human and operating model responses to customer needs.

Autonomous orchestration will work within the thresholds defined, carrying the mass load of decision-making, with exceptions that break defined thresholds. Authority levels remain under the purview of the human user.

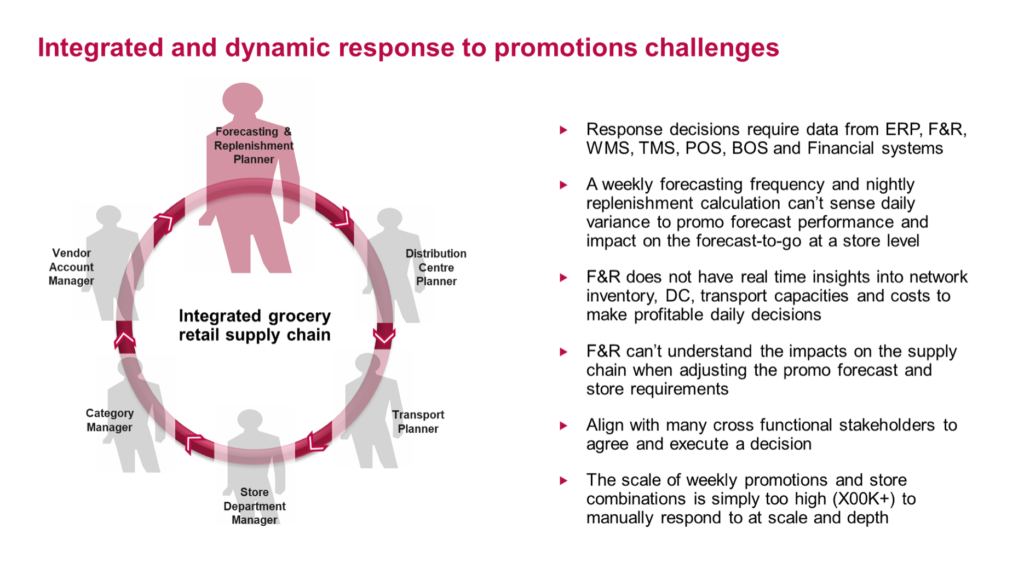

We can highlight this application and opportunity in the context of a retail grocery supply chain, one of the more complex operating models. Based on SKU-location scale, promotional intensity and frequency, and short-time windows, we consider the challenges of optimising promotional activity.

These large supply chains typically have leading application architecture to manage their scale, albeit still largely functional in structure, requiring the human operators to manage the interfaces and consider cross functional decisions off-system.

The scale of promotional combinations is generally too high for planning and operations teams to consider all opportunities in-flight and address all issues in short promotional periods, often leading to a loss of sales and unplanned costs. This is where autonomous orchestration can provide the agility at scale to exponentially respond to this challenge.

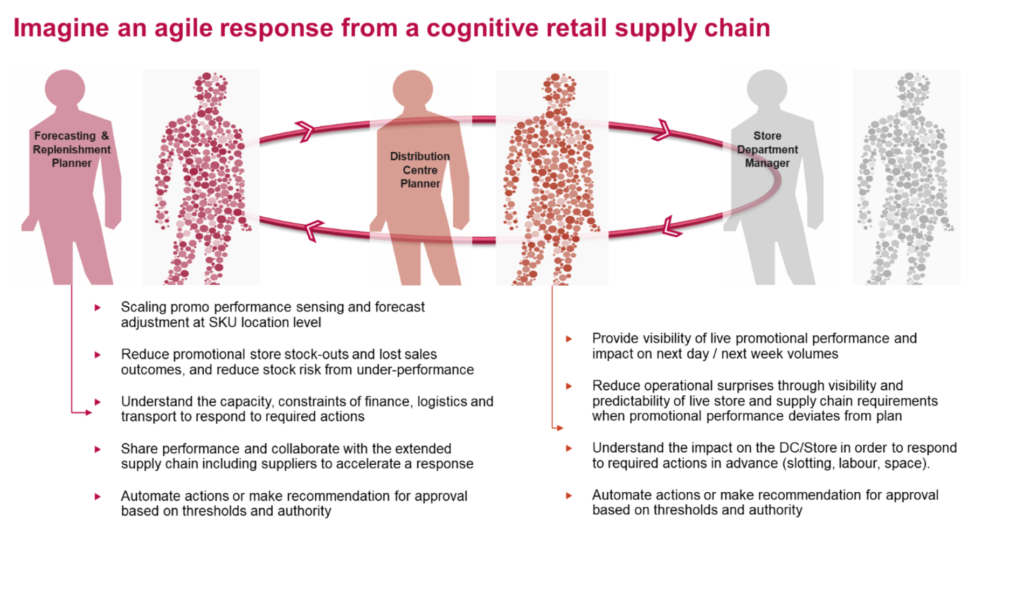

Imagine the value of a scaled ability to sense and respond to optimising margin opportunities at a store/SKU level, considering the cost and availability to execute daily through a promotional period.

Tailored recommendations to each connected user along the supply chain based on their role and decision authorities in a way that is cognitive, dynamic and inter-dependent would drive agile, responsive and value accretive outcomes at scale.

Ultimately these actions can become autonomous within defined thresholds, maximising the coverage of these large retail networks.

There is little doubt that this is the time for autonomous orchestration in supporting the rise of a more agile supply chain.

Autonomous orchestration will elevate the accuracy, automation and scale of decision-making, enabling future supply chains to respond, and succeed in meeting dynamic market requirements in a rapidly changing world in a more agile way.