We must all act now to achieve the UN goal of “meeting the needs of the present without compromising the ability of future generations to meet their own needs”. This urgency is driven by changes in consumer demand, regulation, and unignorable facts about resources and demographics in today’s world. Being more sustainable often makes good business sense, and there is a fundamental sense that it is the right thing to do.

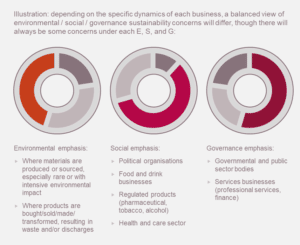

But with louder pledges and ever-more public commitments, where and how should companies actually start to tackle this within their operations? Because every context is unique, there is no simple answer. There are lots of shades of grey and trade-offs to be made.

But it starts with understanding what the sustainable space is in your unique context and making practical changes to get there.

Operations are where the rubber really hits the road

It is obvious that operational improvements can often positively impact sustainability – for example, making production more efficient consumes fewer resources and results in less waste. But it is more than this: operations are where resources are consumed and where we produce everything we need to meet our needs. It encompasses how goods and services are designed and how processes are powered so materials can be transformed and moved through physical networks and infrastructure from suppliers to customers.

To date, too many touted strategies and PR stunts have led to growing cynicism about sustainability credentials and ‘greenwashing’. This reflects how hard it is to turn ambitious goals and strategies into practical actions. Hence there is a need to ‘operationalise’ sustainability and make sure companies are making real change and not simply paying lip service to the notion.

Targeting intervention where it will have the right impact

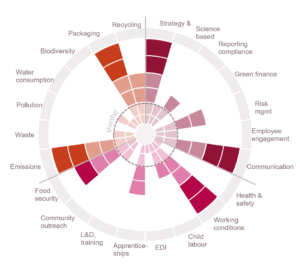

Should a company start by redesigning its products with sustainability in mind? Targeting net zero greenhouse gas emissions, should it target the complete end-to-end value chain or start with manufacturing or distribution? Or zero waste, meaning changes in packaging, as well as operational processes… the possibilities are endless, so where should one start?

The decision process requires deep operational expertise to identify the crucial areas to target first, as well as decide how to make effective interventions, measure performance, set targets, deliver improvements within your organisation and influence key customers and suppliers.

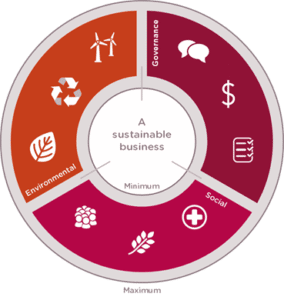

Deciding where to start needs knowledge of the right metrics, access to quality data, and the ability to interpret it to determine good performance or where improvements are needed. Working out this long list needs an understanding of the full range of ‘imperatives’, relating to the environment, society, and governance and their interdependencies.

But there’s another challenge: with the complexity of modern supply chains, how can organisations avoid unintended consequences elsewhere in the value chain?

This could be within your own operation, e.g. replacing ageing traditional combustion vehicles with electric-powered ones might look like a quick win, but this needs sense-checking in terms of the total lifecycle of both vehicles, the local energy mix that will be used to recharge batteries, etc.

It could also be about ‘passing the buck’ further along the chain – for example, outsourcing logistics operations to a 3PL just displaces the problem.

A new mindset from the top down

At its heart, operations management is about making trade-offs, and leaders have long been experts at negotiating between cost, service, and cash. Operations are well placed to embrace a new paradigm; the inclusion of a new dimension, sustainability. Every KPI (Key Performance Indicator) suite needs to incorporate this logic, so decision-making can consistently consider sustainability questions.

Leaders of the future also need to adopt new ways of thinking, getting out of traditional functional siloes or zero-sum relationships between customers and suppliers and instead working as collaborative value chain partners.

Even if businesses are not yet engaged in their own sustainability, they may find themselves being scrutinised by their customers, who are further ahead on this, looking at their extended value chain. Besides failing to manage their own impact, this means a risk of losing business.

Finding the sweet spot – operating within sustainable boundaries

All of this shows that sustainability is full of shades of grey, and decision-making in it is an art rather than a science. Consequently, businesses are starting to think of ‘boundaries’ or ‘thresholds’. This allows you to articulate priorities and targets with clear levers to pull to get practical actions while navigating a changing world and adapting accordingly.

We work with clients to understand their unique value chain, identify where they need to act, and bring together metrics to highlight where minimum requirements are lacking or where current practice is overshooting, whether resources will be exhausted or working practices which cannot practically be maintained. This approach involves recognising unintended consequences and forcing leaders to seek balance across the full spectrum of considerations.

Successfully embedding the change

Sustainability has historically been regarded as a separate ‘stream’. However, to achieve the true intent, it needs to become part and parcel of the day-to-day operation and embedded in decision making. Operations leaders must bring the right technical solutions and expertise to deliver real change to make this last.

This means:

- Understanding the ‘as is’, defining the ‘to be’, and determining the actions needed to close the gap

- Being able to really make the change happen by generating engagement from the organisation, getting stakeholders aligned, delivering effective communication and implementing changes smoothly

- Embedding the changes so that they are truly adopted and lead to lasting change in the organisation

And there’s no time like the present

There are clearly many factors at play giving businesses different ways to optimise their use of natural resources, make business fair and a force for good in communities, and adhere to, and be seen to adhere to, agreed standards. There is no silver bullet, but with sustainability no longer a secondary consideration and instead an essential part of the operation, the successful businesses of the future will be those whose leaders can combine a vision for a new way of making business decisions, deep technical expertise in operations management, and the ability to bring about a change in mindsets and behaviours.

Author: Judith Richardson