The hub-and-spoke model is often considered as the cornerstone of efficient logistics. By consolidating goods at central “hubs” before distributing them to regional “spokes,” it typically promises streamlined operations, better asset utilization, and economies of scale. A well-known example is the Dutch logistics provider PostNL with many “shop-in-shop” service points: facilities owned and staffed by third parties, while integrated into its network and offering PostNL services. But is this model always the most cost-effective approach?

A recent project experience suggested otherwise. We analyzed a client’s logistics operations – with direct-to-consumer (DTC) transport (via in-house fleet and external carriers), company-owned retail stores, and over 100 external spokes. After calculating total cost per item (transportation costs and spoke fees), it turned out that the low volumes and frequent deliveries to external spokes resulted in significant costs. Under these circumstances, a direct-to-consumer model proved more economical.

Key advantages of hub-and-spoke

- Resource consolidation. Centralizing operations at a hub pools labor, technology, and equipment. This leads to more efficient sorting, packing, and loading, often reducing the total number of vehicles or trips.

- Scalability. The network’s structure makes it relatively easy to add or expand spokes without a full redesign. As volume grows, the core hub remains the central node for handling freight.

- Efficiency in high-density regions. For areas with high shipment volumes, centralized sorting can lower unit costs and reduce empty miles, reduce transportation costs, simplified scheduling and fleet management.

Limitations

- Double handling. Goods often require at least two touchpoints (at the hub and then at the spoke). This can introduce higher labor costs, greater risk of damage, and the potential for delays. Handling inefficiencies can quickly accumulate, undermining the cost-effectiveness the model aims to achieve.

- High hub costs. Building and maintaining a central hub, often in a strategic but expensive location, drives up overhead. Robust infrastructure, sorting technology, and staffing requirements further add to expenses.

- Inefficiencies in low-density areas. Where volumes are sparse, the per-item cost of transportation via spokes can quickly offset gains from consolidation. Excess capacity and infrequent shipments can make the model unprofitable.

- Potential customer inconvenience. Consumer expectations for rapid, reliable (same/next-day) delivery are growing. Customers increasingly value speed, and a one-size-fits-all hub-and-spoke approach may struggle to meet the delivery performance of direct shipping.

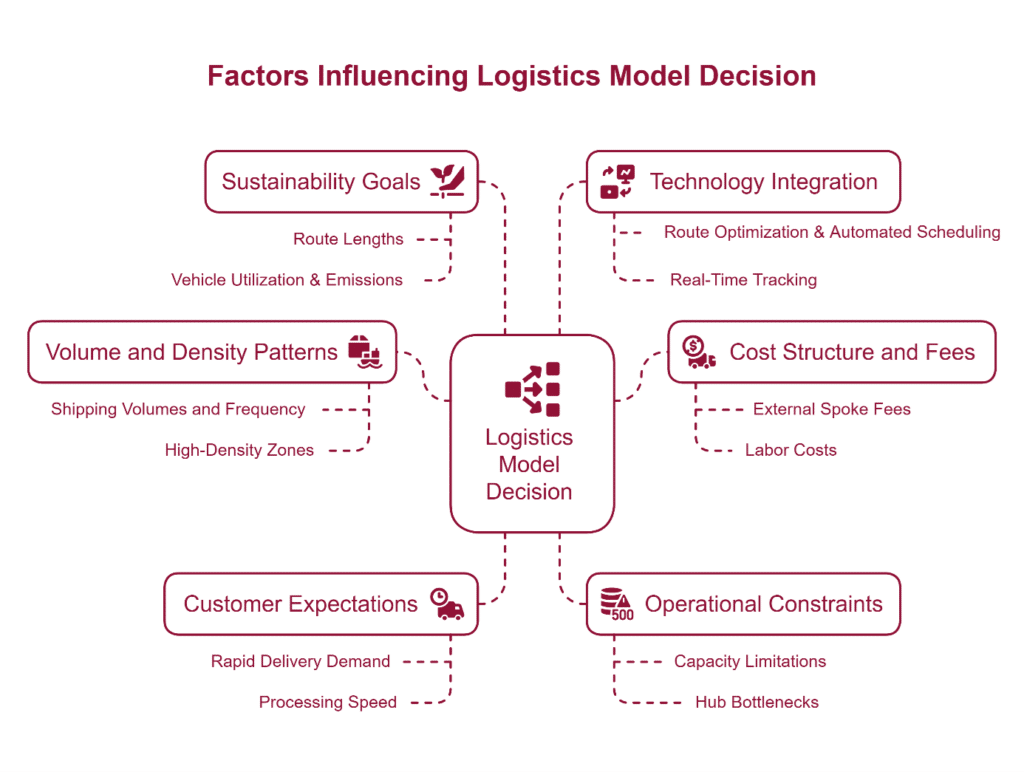

Factors to consider in deciding your model

- Volume and density patterns. Analyze shipment volume, frequency, and geographical distribution. High-density zones often favor hub-and-spoke; low-density areas may benefit from direct shipping.

- Cost structure and fees. Evaluate external spoke fees, labor, transportation, and real estate costs. Low utilization across many spokes quickly becomes uneconomical.

- Customer expectations. If customers demand rapid delivery, consider whether hubs can process shipments fast enough or if direct routes might better serve time-sensitive orders.

- Operational constraints. Evaluate capacity, workforce availability, and technology infrastructure. Hub bottlenecks can undermine efficiency and increase per-item costs.

- Sustainability goals. Consider the environmental impact of driving goods via multiple spokes versus direct deliveries. Analyze route lengths, vehicle utilization, and emissions to ensure alignment with green objectives.

- Technology integration. Advanced route optimization, real-time tracking, and automated scheduling can streamline both hub-and-spoke and DTC models.

When direct-to-consumer may be more viable

In scenarios involving lower volumes, wide geographic dispersion, or frequent deliveries, direct-to-consumer can outperform hub-and-spoke. Modern technology such as route optimization, real-time tracking, and demand forecasting helps manage a decentralized network effectively. Bypassing a hub cuts handling steps and can speed up delivery.

However, pure DTC models can be expensive in remote regions, where mileage and time per delivery are high. A hybrid strategy often works best, leveraging hub-and-spoke in high-density zones and direct delivery elsewhere.

Practical steps to optimize your model

- Conduct regular cost analyses: Periodically review shipping data, spoke fees, and per-item costs to detect inefficiencies.

- Leverage technology: Implement route optimization and real-time tracking tools to better manage both centralized and decentralized models.

- Adopt a hybrid strategy: Consider a hybrid model, retaining hub-and-spoke advantages where volumes are dense, while shifting to direct-to-consumer for low-volume or geographically dispersed deliveries.

Ultimately, no single approach suits every business. A data-driven review of volumes, distribution patterns, customer expectations, and sustainability objectives will identify the most profitable and resilient path forward.

Sources

- Bowersox, D. J., Closs, D. J., & Cooper, M. B. (2019). Supply Chain Logistics Management (5th ed.). McGraw-Hill.

- Christopher, M. (2016). Logistics & Supply Chain Management (5th ed.). Pearson.

- Ghaffari-Nasab, N., Ghazanfari, M., & Teimoury, E. (2015). Hub-and-spoke logistics network design for third party logistics service providers. International Journal of Logistics Research and Applications, 18(1), 49-61. https://doi.org/10.1080/17509653.2014.992994