Supply chain digitalisation is everywhere. It’s changing the whole landscape, from demand-side process patterns and how people order, through to 24/7 requirements and expectations, and increasing demand volatility. Furthermore, this has had a dramatic impact on supply processes, which now need to respond faster than ever before to keep up, perhaps even faster than the human brain can manage.

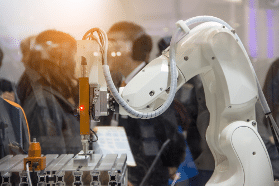

Fortunately, supply side digital solutions are advancing to meet the demand challenges. Cloud computing power, robotic process automation, cognitive learning/AI and algorithmic planning are all charting a new way forward. But before you think humans are out and robots are in, for it to work successfully, digital based transformation still needs to be deeply anchored in management and planning systems. And that successful blend requires an overall understanding of both that only humans can bring – at least for now.

The functional requirements we need in such planning systems will be different in the mid to long term, but for now it’s more about the things you need to build around existing systems to consolidate, analyse, synchronise data and fine tune parameters. For example, Robotic Process Automation (RPAs) can help assemble and structure data, and outputs from algorithms can drive insights, particularly in the white space between functions.

But in the future, RPA is also ready to automate numerous other supply chain planning tasks that will eventually scale back the necessity for constant manual oversight of planning process steps.

This may sound far-fetched, but so did driverless cars, and look where we are now. The science exists and is being deployed. The bold and innovative are beginning to set up processes that analyse vast amounts of data at a granular level to provide performance feedback. They are starting to use self-correcting supply chain processes and getting to grips with how to integrate this with new and existing management systems. They are exploring how to holistically model and perform rapid what-if analysis with greater precision. This concept goes far beyond just having software that runs scenarios and displays ranked results of their outcomes and will end up with machines making the decisions entirely and actions being filtered down through the rest of the supply chain.

At the heart of it, the innovators are embracing more significant levels of algorithmic planning, with data that can provide answers in seconds based on an optimal set of variables. It won’t be long before the rest follow.

Handing over control of entire processes or key planning steps to systems may seem counter-intuitive, but it is the way the world has moved, and it is something that should be embraced, not feared.

But what does this mean for our human planners who work in the supply chain? Not fewer jobs, but hopefully less chronic overworking and involvement in day-to-day minutiae, data entry and relief from tedious manual work. There will be brand new co-worker relationships and degrees of collaboration with technology and AI.

Likewise, as the use of robotics increases, we may start to see Chief Robotics Officers (CRO) appearing on our Boards working alongside the more traditional functional heads. And one of the critical requirements of the CRO will be how to bring about the perfect balance between human and electronic resource. How to weave the strengths and weaknesses of both human and electronic counterparts and blend engineering, IT, logic, problem-solving and human capital management skills.

Your new co-workers may already be among you. It’s time to make friends.