On-time delivery (OTD) is the main metric to measure the efficiency of supply chain processes in your organization. It is an indicator of how capable your organization is to meet customer demand in terms of the requested delivery date (RDD). Failing to meet your customers’ requests can lead to all sorts of negative outcomes, in the worst case even losing your customers to competitors.

Outside-InTM thinking

At Argon & Co we often experience a vast array of different interpretations and calculations of the OTD metrics. This indicates that customer-centric Outside-InTM thinking is not at the heart of every organization, in other words putting its own interests above those of their customers. In many organizations we have taken the following observations, leading to a distorted view on OTD as KPI of your supply chain performance:

- OTD is simply measured as a ratio of the number of units on time divided by the number of total units shipped on a monthly base as an average

- It is not clear how the number of units on time is calculated;

- OTD calculation reference points are unclear, e.g. are they based on the requested delivery date (RDD), first confirmation date (CDD-1) or last confirmation date (CDD-2)

- The shipment date is usually the actual delivery date (ADD), not the actual delivery date on customers premises;

- Early deliveries without customer approval (e.g. month end pressure) are defined as delivered on time;

- OTD is calculated on order level, not on order line level;

Quite frequently we see surprised looks when we present the actual OTD Outside- InTM results that are not anywhere near the 90% that was expected by the management.

Measure your Span

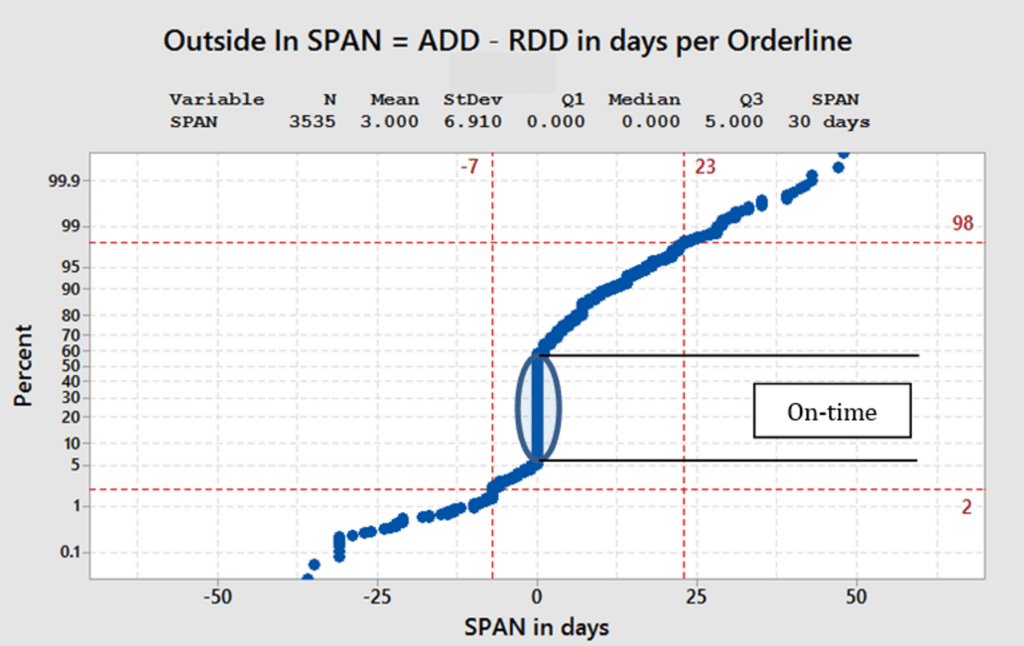

From a diagnostic and executional perspective, it is much more powerful to measure and analyse Span, a metric developed by GE. Outside-In Span takes the customer’s voice as a starting point. Process performance is measured against the requested delivery date (RDD) at order line level, not order level. It generates a variance-based view of each order line delivery performance. The Outside-In view prevents performance data being manipulated simply to ‘manage the metric’.

In the example above in only 53% of all order lines in the observed period, the actual delivery on site did match the customer requested delivery with a Span 98/2 of 30 days. 5% of all orderlines were shipped too early (up to 35 days) and 40% of all orderlines were shipped too late (up to 48 days).

Identify and eliminate root causes

The goal is to reduce the SPAN of 30 days to a minimum, bringing as many orderlines to the centerline. In order to achieve this, the following issues need to be resolved:

- Why does this company allow orderlines to be delivered up to 35 days early?

- Why does this company deliver up to 48 days late?

The underlying root causes for the issues above are often planning and operational issues that need to be tackled in order to reduce SPAN. To understand the root causes of early and late deliveries, detailed process analysis is required. In order to improve your customer experience these root causes need to be identified and eliminated, which often requires a paradigm shift in terms of operational and supply chain strategy.

Argon & Co can give you insights in what your customers actually experience looking at the OTD SPAN. Introduction of the Outside-InTM SPAN metric allows you to control and improve your supply chain.