We are being swamped by data. Analysis and visualisation tools are working wonders. Investments in information, planning and business management systems (such as ERP, APS and WMS) are skyrocketing and there are experts abound!

But for you, as a leader at the forefront of your business, the COO or manager of your division, how has this revolution really benefited your day-to-day operations? Would you say that it’s still to come or that Data Science has already changed a fundamental aspect of your leadership style, namely the way in which you make decisions and delegate?

In 2023, with the help of processes that have never been so interconnected, Agile and Lean, have we finally arrived in the era of Data-Driven Leadership?

On our side, how do we define Data-Driven Leadership? It is the power that allows directors and first-line operations managers to make better decisions, so that they can continually improve performance in terms of cycle-times, quality, capacity, productivity, and product development, all while supported by data that they know is reliable, complete, and understandable.

Some history

The most senior among you will remember the Black Belt and Master Black Belt trend from the end of the last century, via the famous Lean Six Sigma developed by Motorola, popularised by Honeywell and finally transformed into true corporate culture by Jack Welch as the head of General Electric.

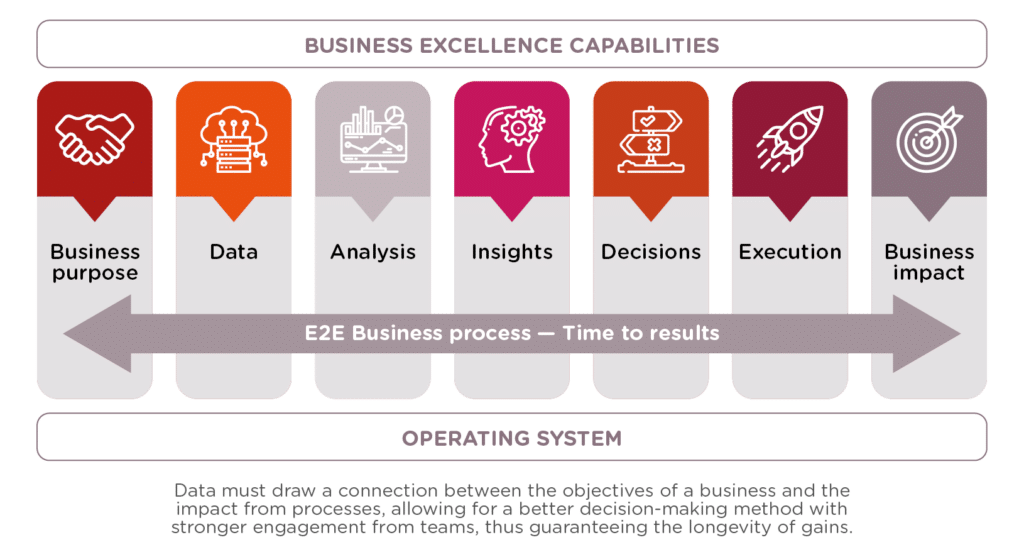

Data-Driven Leadership is the method of exploiting raw data, essential for creating the link between the key business objectives and the actions necessary to achieve them, at the same time as identifying the ongoing actions that can be abandoned. The impact of each improvement lever can be quantified in advance in order to prioritize projects and resources and ensure all departments and teams are aligned around one common roadmap.

What happened to the phenomena that shook up the way in which we solved problems and achieved breakthroughs in performance by relying on decisions based on validated data, clear hypotheses, causes quantified by statistical analyses and some simple correlations, all of which were accessible with two to three weeks of training followed by lots of practice?

For the last twenty-five years, while the availability of data has been increasing, so has the power of analytical tools skyrocketed and data scientists are found everywhere in businesses. The practical use of data as a concrete decision driver (or Data Driven Leadership), has still not to this day followed the same path, but instead has stagnated. The Black Belts, the true data science pioneers of the last century and those embodying Data-Driven Leadership have been struggling…

Yet, without Data-Driven Leadership at the very top level, a business, despite its technological investments, will pass beside significant performance gains and will only receive a tiny portion of the potential savings, thus considerably reducing the ROI of their tools and data infrastructure.

The Data-Driven Leadership method is not just for leaders. Nevertheless, it requires their commitment by example: making data-based decisions starts at the top!

What is Data-Driven Leadership?

Data-Driven Leadership is the method of exploiting raw data in a way that is vital for improving execution by drawing a connection between key business targets, the actions to take, and the actions to abandon. Prior to jumping onto changes, the impact of each improvement lever is quantified in order to prioritise actions and resources and align roles, departments and teams on the road to a common goal. It demonstrates a clear causal relationship between your decisions and actions and your business results. Everyone, at all levels of the organisation and within each function, is focused on the common business objective and can evaluate their contribution to total performance.

Data-Driven Leadership is therefore a set of processes, methods and behaviours that need to be implemented to transform the culture towards data-based decision-making. Nowadays, Data Scientists are still not the decision-makers, don’t always have detailed understanding of the processes, and are even sometimes totally disconnected from the “operational reality”.

Data-Driven Leadership allows a manager to independently evaluate whether an increase in established capacity will be enough to meet additional demand without the need for substantial investment, or whether CapEx is necessary. It is also the moment when the key stakeholders, decision-makers or first-line supervisors will understand when a performance indicator is simply the result of a variation inherent to the process and can be ignored or, on the other hand, when this should alert them to the occurrence of an anomaly that requires action. The Data-Driven Leadership method is not just for leaders. Nevertheless, it requires their commitment. Making data-based decisions starts at the top!

Demonstration by example: Data- Driven Leadership on a strategic level

Several years ago, a global electrical equipment group publicly announced their largest single investment in 150 years, for an amount of 400 million dollars, into one single site. It was intended to double capacity in a factory that hadn’t been able to deliver projects on time, thus risking harsh penalties, and that could not, according to their experts, meet the demands of a fast-growing market.

We were on site at the time, tasked with reducing quality defects, which were identified as one of the causes of delays as the reworking of the defects was a long process. Our war room was located at the top of the extrusion tower. During each shopfloor walk, we noticed that the extruder was not operating. We asked the head of the business unit about how often the machines were used. Having confidence in us as a result of our work on the quality problems, he asked us to analyse their capacity usage and investment plans.

Supported by data, we showed that it was possible to increase the volume of the factory’s finished products by 40%, without investment, by driving through a data-based improvement program together with their operational teams. After 18 months of diagnostic and implementation, the production volumes had increased by 33%, with the same product mix, and as expected, without any investment! After two years, the same old factory was producing 60% of additional finished goods and 74% of additional extruded volume! Construction of the second extrusion tower was finally stopped. The projected improvement potential – 40% without CapEx – and the business case for the 400 million dollars investment to achieve these same volumes were, however, based on the same data. The only differences between the two approaches were the granularity and depth with which we used the business’ data and the connectivity between data sets, shopfloor observations and on-site exchanges.

In 90% of cases, performance improvement is related to unexpected or counter-intuitive factors which management and local experts didn’t have on their radar screen.

Data-Driven Leadership at an operational level: a growing number of examples

On a more operational level, many small performance improvements were seen within several operational teams: in production, logistics, R&D, after-sales, and even financial management. A more astute understanding of the processes, a more granular analysis of the data, with a high connectivity between data and business priorities, on-site observations and ongoing exchanges with experts who operate these processes daily is key.

In 90% of cases, performance improvement is related to unexpected or counter-intuitive factors which management and local experts did not expect. In reality, the factors that experts and operators raise during the initial exchanges as being the main or one of the main causes of their under performance and problems have a very small impact in 90% of the cases encountered. Therefore, the following actions are of fundamental importance for those who wish to drastically improve their long-term performance:

- Involve operational teams and experts

- Validate the correlation and inherent causality described in their initial hypotheses

- Share the reasons why, in 90% of cases, their main suspect is in fact innocent!

- Continue to delve into and look for the true causes, which may not be the ones you first think of…

- After these data-based validations, define and implement solutions along with them

Let’s talk about another example: the humidity level of raw material. It was considered by all the process experts and control room technicians to be one of the most critical factors – if not the only critical factor – of material yield. It seemed obvious, and an investment of 3 million euro was already approved for a second dryer. Two days of granular data analysis with process experts demonstrated that an additional reduction in humidity level using a second dryer would have in fact no impact on the production yield, saving the company 3-million-euro investment in only two days of work.

To complete this section with a final example. In a logistics company with five warehouses across Europe, distributing 500,000 agricultural machinery and construction industry components, Process Mining, once again based on a granular use of data combined with shopfloor understanding, allowed the company to analyse in detail the blockages, alternative paths and duplications, thus identifying the anomalous workflows to be eliminated. The clear and rapid analysis of productivity data, telephone availability of the after-sales team, and the quality of preparations, with the implementation of the subsequent improvement actions, has allowed the company to improve their service rate by 20 points in four months, as well as improving the morale of employees who were largely affected by a long period of recurrent client dissatisfaction.

Unite old concepts with the current and future power of data

The question being asked today is whether the increased availability and accessibility of data has already brought about changes to the style of leadership in 2023. Has it allowed leaders to take decisions, manage and delegate differently? Have improvements in performance been confirmed?

Managing “on instinct”, the combination of experience, ability, and the need to act fast, is it still the norm, even though managers will occasionally call upon specialists to clarify certain strategic decisions using data. Day-to-day decisions made by leaders are still not sufficiently based on data and some businesses are still not clearly Data-Driven.

Still today, too many managers say: “I’ve only used a fraction of the Small Data that exists around me, what am I supposed to do now in this ocean of Big Data?”

In most sites, factories, warehouses, R&D centres, sales management centres, within large groups predominantly in the top three globally in their industry, it’s clear that up to now, the abundance of data has not helped with making good investment decisions, with ensuring the smoother development of new products, or with resolving recurrent problems. The increasing quantity of data available seems to simply lead to an insistence that each and every deviation from the norm, as shown by our many indicators, should be investigated. Knowledge that can transform data into value still seems to be lacking, even though very pertinent ways to use data, often simple and rapid, can lead to very large gains.

To ensure that this growing accessibility to data can finally lead to drastic improvements in operational performance, including the environmental dimension that is now so important to everyone, integrating Data-Based Leadership competences is essential. This requires at least four major developments in managerial practices:

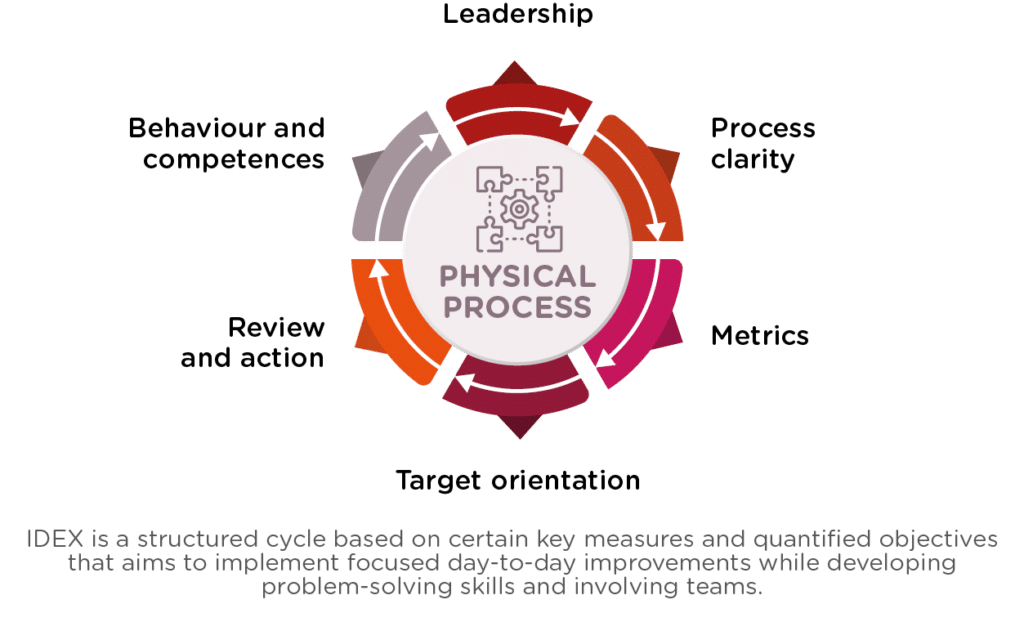

- Position data at the heart of your daily decision-making, i.e., your routines, in order to use the data and guide your decisions and actions towards daily continuous improvement. You should focus on the small number of key indicators that create a direct link between real-time variation and a business objective. This has become more accessible now that Data Visualisation has made considerable progress in terms of ease of implementation and sharing knowledge. This guarantees that the daily interrelations throughout the organisation, from management to machine operators, are focused on quantified and validated information that will identify actions that are aligned with the common objectives

- Train your Operational Excellence teams to become high-level change agents, the new Black Belt data experts and change experts, with strong internal credibility based on their knowledge of processes and people

- Mentor operational managers in this new decision-making methodology. The daily practice of data-based decision-making and the questioning of long held organizational beliefs is a profound change that requires practice, and which definitely needs a period where “mistakes are allowed”

- Make sure that the organisation continues to learn. Continuous improvement has not evolved very much in the last twenty-five years, while enormous volumes of data and new visualisation and modelling tools have become available, calculation power has grown, and increasingly specialised data scientists have come to enhance all levels of a business.

Conclusion

Without a strong cultural transformation across all levels of a business, technology and data science are limited in their potential. Clearly, this change will come to each business sooner or later, but it is a leader’s responsibility to accelerate this change. Without Data Leadership the examples shared in this article would certainly not have achieved the remarkable results that they did.

Published originally in French for ADD12 magazine