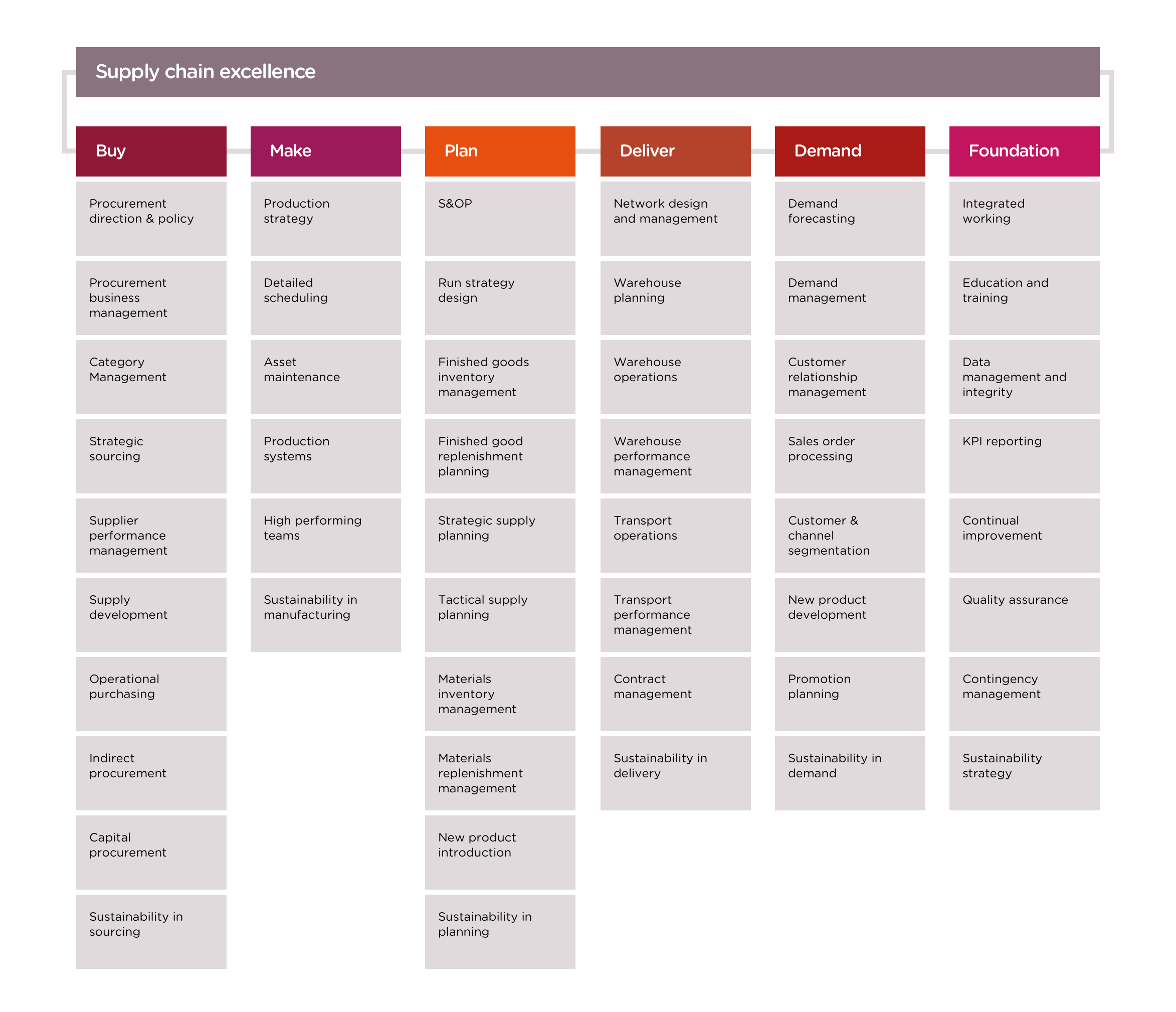

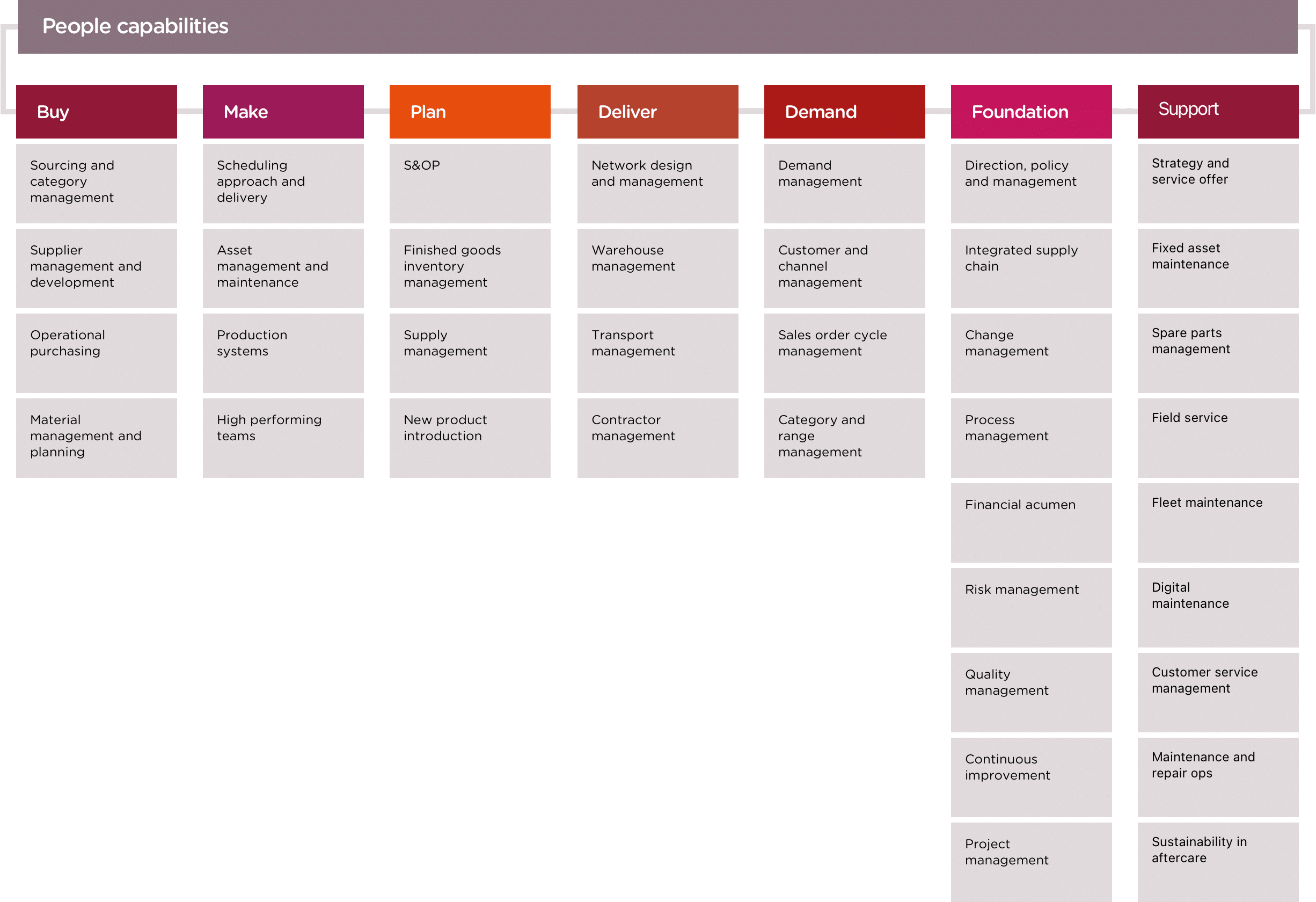

scprime® is Argon & Co’s powerful improvement approach, combining process and people capabilities to ensure that the right people are in the right jobs, consistently doing the right things.

Based on benchmarking, an objective assessment of capability and a toolkit of implementation techniques, it defines supply chain excellence in terms that are meaningful to each specific organization and ensures that improvements are sustainable. It is how it is applied that sets scprime® apart, enabling companies to dramatically improve supply chain capabilities and significantly reduce cost.

scprime® benefits

scprime® drives a focused and effective improvement program, hard-wired to strategy and objectives.

It is the result of decades of practical experience, achieving long term improvements in companies in over 30 countries on five continents by identifying supply chain excellence in terms that are meaningful to each specific organisation. It has been proven to achieve a step-change in performance, with long term improvements already seen in over 20 countries on five continents, by aligning supply chain strategy with business strategy. Benefits are significant: operating costs are often reduced by 15-20% and working capital by 10-15%; responsiveness and service levels are improved and are more consistent, allowing greater innovation and driving increased sales; staff is developed according to the specific needs of the role, focusing on capabilities rather than job descriptions so they are equipped to carry out what is expected of them.

The focus of scprime® is to drive improvement rather than simply provide scores on a scale of excellence. scprime® impacts a business in two stages:

- Functional improvement – getting better at making, moving and buying, for example

- Cross-functional improvement – developing more effective planning and other business-wide processes

The potential supply chain benefits are considerable, especially in multinational businesses.