Supply Chain Design Series Part 2 (visit Part 1, here)

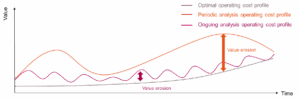

In today’s volatile environment, the pace of change is too fast — and the risks too high — to treat supply chain design as a once-every-few-years exercise. Leading organizations are replacing episodic design efforts with continuous analytics and real-time insights.

It’s not just a shift in cadence. It’s a shift in mindset — from reactive to strategic, from theoretical to operational, from lagging to leading.

What Continuous Supply Chain Design Really Means

Continuous design is more than running network optimization models on a tighter loop. It’s a cross-functional capability embedded into decision-making — always available, always relevant, and always aligned with the business.

When done right, continuous design allows organizations to:

- Act faster: Decisions that once took months now happen in days — or hours — enabling quick pivots when market conditions change.

- Capture more value: Frequent alignment reduces the risk of wasted investments and unlocks more of the potential savings or service improvements.

- Tighten strategic alignment: Modeling becomes a living tool, directly linked to operational imperatives and executive goals.

- Shorten time-to-value: Organizations don’t need to wait for the “next big initiative.” They can identify, test, and implement improvements iteratively.

Going Beyond Traditional Notions of “Design”

Modern supply chain modeling isn’t just about footprint or flow. Today’s platforms support a broader range of decision types and use cases — spanning the strategic, operational, and tactical levels.

That includes:

- Strategic optimization to reveal the ‘one best answer’ assuming static conditions over a given timeframe

- Operational scenario analysis to test other static options for resilience, risk management and building disruption playbooks

- Tactical simulation to observe the impact of behavior (demand volatility, logistical risks, supplier risks, operational risks, industrial relations unrest, and interconnected network failure) over time on operating costs, inventory, labor, service and capacity.

- Predictive analytics tied to demand patterns to better inform tactical planning options

Design, planning, and execution are no longer siloed. Continuous analytics brings them into one connected loop — and with that comes greater agility, foresight, and confidence.

Tools and Talent Aren’t Enough — Alignment Is Key

Technology and modeling expertise are critical — but not sufficient on their own. To realize the full value of continuous design, organizations must also build trust and alignment across functions.

What makes the difference?

- Clear priorities and shared objectives: Business leaders and modeling teams must align on what success looks like.

- Strong leadership: A respected champion can bridge organizational silos and create buy-in from stakeholders.

- Strategic use cases: Start with 1–2 initiatives that have clear value and high impact. Build momentum through early wins.

- Engaged users: Involve business stakeholders throughout the process to build ownership and ensure relevance.

- Simplified interfaces: Democratize modeling by giving non-technical users access to insights through intuitive apps or tools.

Design as a Continuous Advantage

When supply chain design becomes continuous, it becomes more than a strategic planning tool — it becomes a source of competitive advantage. The organizations that invest in this capability don’t just respond to change. They shape it.

And when it’s time to scale, they’re already moving.

Reach out here if we can help you become a catalyst for positive change in your organization.

This is part of a series, see part 1 here, Is It Time to Rethink Your Supply Chain Design? Here’s How the Best Know When to Act.

For part three, From Periodic to Proactive