The Design of High Volume Case Pick Operations

ABSTRACT

Detailed design of conveyor systems involves analyses that reach far beyond simply the selection of the most appropriate system concept. This paper discusses issues and trade-offs in systems for batch picking and sortation of full cases.

INTRODUCTION

As a consultant and system designer, I have always been interested in choosing the right functional technology, with the proper cost/benefit relationship. More recently, as I moved about in the world of the system supplier, I rediscovered that choosing the “right” technology still leaves a great deal of system design work to do. Of course, as in most technical areas, there are rules-of-thumb and accepted practice to serve as guidelines. Ultimately, there is the panacea of simulation to “ensure” system viability.

However, rules-of-thumb do not break new ground. And, today’s imperative is often aimed at “breakthrough” improvements. Simulation cannot invent trade-offs in system design. It can only help to evaluate those issues that we remember to test as the model is built. The following text outlines some of the issues I have encountered regularly in the design of case picking systems. I hope that by reading through these, the reader will be more educated and will understand what questions are important to ask, and if the reader is a designer, I hope these comments will help complement what you already know but in a way that improves your designs.

Over the past few years I have become increasingly interested in case picking systems that employ batch picking and sortation. They are particularly interesting for several reasons:

- Order picking: Already documented as the dominant cost element in warehousing, has been found to be mostly “not” picking. Pickers don’t spend much of their time at the pick face. Most of their time is spent traveling around, waiting to get at a pick face, discovering that what they come to pick isn’t there, off loading the picked orders, organizing their work, etc. Consequently, there is a great incentive to reduce the non-picking portion of the job.

- Evolving logistics systems: Based on rapidly shifting customer demands, are creating more orders of smaller size to satisfy the same business volume as before.

- Centralizing inventories: To improve availability at lower total inventory levels, by capitalizing on creative transportation alternatives provides interesting economies of scale for mechanization.

- Now that distribution is everybody’s “strategic weapon,” the focus is back on reducing costs

ORDERPICKING ENVIRONMENT

Order picking generally creates a change in the unit of handling for individual products. For example:

Receiving/Storage unit Picking/Shipping unit

Truck Load Pallet Load

Pallet Load Case

Cases Pieces

Orders are often comprised of products in each handling unit, depending on order size and product popularity. Usually, each handling unit type comes from different sub-system-i.e. full cases and individual pieces of the same product are not selected from the same stock location.

Each of these handling unit conversions represents an interesting, and a real part of what must be considered in warehouse design. To illustrate some of the areas where we can use some help in evaluating trade-offs, I would like to focus on the pallet-to-case conversion, which is otherwise known as “the case picking process.”

CHOOSING AN ORDER PICKING PROCEDURE

Traditionally a picking list for a customer order is given to a picker who travels the pick path, adding cases to a pallet or roll cage as he/she goes. Large orders may require interrupting the process to drop off full pallets as they are completed. Alternatively, a large order may be segmented and assigned to several pickers, thereby reducing the elapsed picking time.

Order picking has several advantages, such as:

- Simple paper pick lists may be used.

- One person can be made responsible for an entire order.

- Products may be easily grouped into families along the pick path to ensure that policies, such as placing the heaviest products on the bottom of an outbound pallet, may be easily observed

- Activity-based location assignment can significantly reduce the pick path for an order.

- Since pickers are each picking one order and operating independently, it is easy to assign work, keep them busy, and measure results.

However, as product offerings increase (SKU proliferation), the warehouse begins to fill with more and more material. Consequently, the pick path gets longer, and as orders or order quantities become smaller, the path must be traveled more frequently. Congestion and delays can occur near fast-moving products in the larger volume facilities.

The challenge in larger facilities is to develop a system that maintains most of the advantages of smaller, order picking environments while addressing the problem of increasing levels of “not” picking.

Batch Picking

One alternative is to batch the picking requirement for several orders and then sort the cartons that are picked to individual orders as the picker goes along. This is known as multi-order picking or cluster picking. In its simplest form, a picker may take two pallets at a time along the pick path and simultaneously pick two orders. This approach can be extended by pulling a “train” of several pallets or roll cages. In this way most of the benefits of simple order picking are maintained. The technique is limited by the length of the train to about 4 or 5 orders. As the train size grows, aisle widths and congestion become bigger factors.

Wave Picking

The next variation is radical. An interesting and even more powerful concept is to accumulate the requirements for a larger number of orders (50-100); pick them as a batch and convey the cartons to a high speed sortation machine and then divert them to chutes/spurs dedicated to each order. At the end of the spur they are loaded onto a pallet or roll cage by a second operator. This is known as “wave picking”. The general principle is to handle each case efficiently two times, rather than inefficiently once. Clearly, the rate for each of the two handing steps, batch picking and container loading, must be considerably more than twice as fast as the single step in traditional serial order picking to make the concept worthwhile.

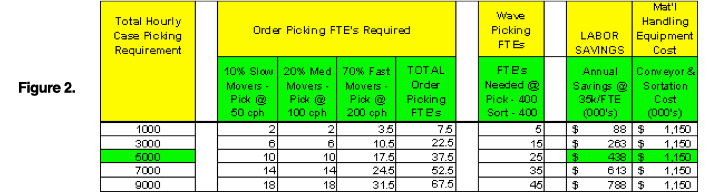

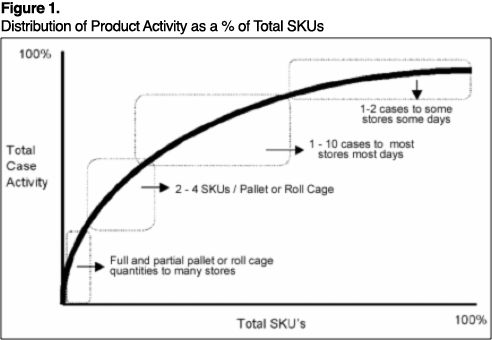

The table in Figure 2 shows that labor savings sufficient to justify the cost of mechanization only occurs when the rate for picking individual orders is expected to be slow and the total case picking requirement is high. This occurs when the same product is required in small quantities for many orders at the same time. This is a common occurrence in centralized distribution of high volume consumer products to a chain of retail stores. Groceries are a typical example. Shoes, Hardware, and PC Software are other examples.

While batch picking is more efficient, it only starts to pay off at higher volumes

Because very popular products may be ordered several cases at a time for each store/order, they generally can be picked at higher rates in the traditional order picking fashion. The midrange and slower-moving products are more time consuming to pick and represent the best opportunities for wave picking and sortation. Once a major equipment investment can be justified for those products, it sometimes makes sense to use the same method for the fast movers as well, if there is sufficient capacity.

CHOOSING MATERIAL HANDLING EQUIPMENT

The picking of cases of product in wave picking environments may be accomplished in a number of ways. Several common ones are listed below. A few are illustrated and described below.

Pick-to-pallet on pallet jack

This is the simplest and most common way to accumulate cartons for a batch of customer orders. The investment in equipment is low, however, it is difficult to pick from any location except at floor level, so the pick path may be quite long. Aisles must be wide enough to accommodate pickers passing one another and most probably, lift trucks for storage and replenishment moves. Cases must be rehandled to induct them onto the sorter.

Pick 2-4 batches to pallet or roll cage train

This method is very similar to picking to a pallet jack, but permits several batches to be combined to reduce the number of times that a picker must travel the pick path. To make the picking most efficient, a special pick list aggregating the requirements for the batches and then indicating the allocation by batch must be prepared.

Order Picking Truck

This method still requires a separate handling step to induct the picked cases onto the sorter, but the pick path can be much shorter because the orderpicker can access several levels in the pallet rack. It is especially useful for very slow-moving products. With a narrow aisle, the picker can reach products on both sides of the aisle, but it is difficult(if not impossible) for more than one picker to share the aisle or to perform replenishment operations during the time of picking.

So far, all of the picking technologies described have required that the wave picker perform two operations: first, pick the item and then induct the item onto a conveyor to go to the case sortation system. In order to improve the throughput and efficiency of pickers, the following case pick technologies can be employed:

Pick-to-belt

Cases are placed by the picker directly on a belt conveyor from pallets along the pick face. Pickers walk from one pick to another to complete the requirements for a batch in their zone and then repeat the process for each batch. A zone may be defined as large or small as necessary to permit the picking of all cases within the allocated batch time. Belts are typically placed on mezzanines over one another to improve space utilization.

Pick car

This is a special device that combines the features of an orderpicking truck that can access multiple levels of pallet rack and pick-to-belt in which picked cases are conveyed directly to the sorter. Because only one pickcar may be placed in an aisle, the case flow rate from that aisle is limited by the capacity of one picker.

Pallet-to-picker

When the number of cases of a single product required for a batch will consume a full pallet, the pallet may be brought directly from reserve storage to a special depalletizing workstation where cases may be efficiently transferred to a conveyor infeed to the sorter. In some systems, this is done even when the batch quantity is less than a full pallet. However, the unused portion of the pallet must be returned to storage or to a staging area until it is needed again. The ergonomics of the depalletizing station can be improved with the use of lifts, turntables, and even mechanical lift assistance as shown in the picture to the left.

Robotic picking / Depalletizing

Using robots or other mechanical devices to transfer cases from a pallet to a conveyor is an extension of the pallet-to-picker method. Some systems use a robot to transfer one case at a time, while others transfer an entire layer from the pallet.

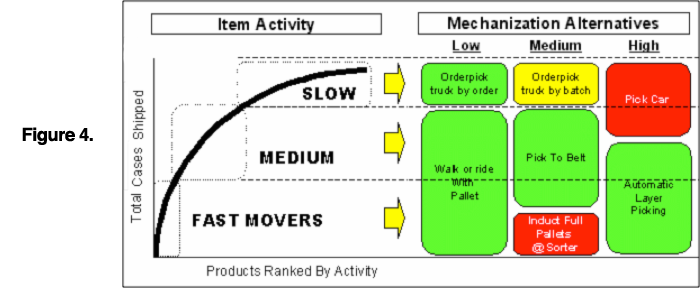

The selection of the right material handling technology depends on an analysis of total volume, individual product volume, frequency of pick of a product, space availability, cost, and a number of other factors. A combination of methods may be used, but using more than three may be complicated to plan and manage. Figure 4 on the following page uses the product activity distribution to illustrate some possible combinations of technology for varying levels of mechanization.

ADDRESSING THE ISSUE OF LABOR IMBALANCES WHEN WAVE PICKING

When orders are picked by wave, a facility will be organized into zones and operators assigned to work within those zones. This is done to keep the pick tours relatively short as an operator may only be assigned picks that are within his zone.

Unfortunately, for each wave/batch of orders to be picked, the biggest challenge is to synchronize the flow from the various picking zones. Some of the factors to consider in both system design and operation include:

- The number of cases from each area for each batch may vary greatly.

- The workload in a zone usually requires fractional operators for each batch, so that when “whole” people are assigned, the zone will have a slight over, or under capacity and as a result, will finish ahead or behind the other zones.

- Maintaining a family grouping of products further complicates the assignment of stock locations and the control of picking activity.

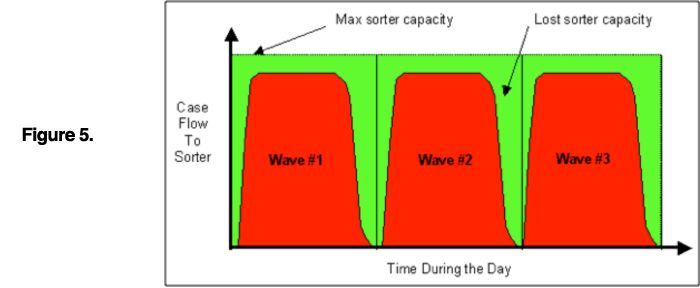

The implication of these design issues is that when products are picked in batches from multiple pick zones, they do not all arrive at the sorter in the same time window. Travel distances, varying pick rates, and an imbalance in the number of cases for a batch from each zone will cause some zones to finish early and others to finish late. This can lead to a lot of operators standing around waiting for the next wave to begin while others in more heavily hit zones scurry to finish their assignments. This also means that for some period of time towards the end of the wave, the sorter isn’t being fully utilized.

Buy Excess Capacity

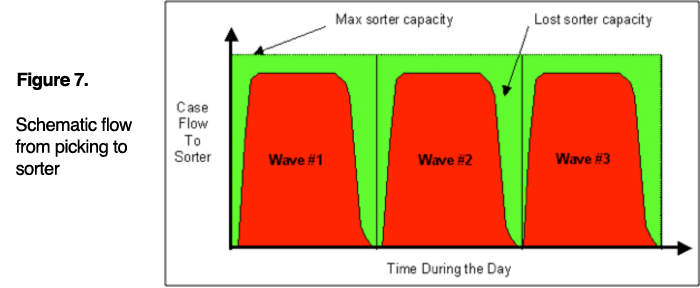

In many facilities, this issue is simply, although expensively, addressed by purchasing more-than-sufficient capacity in all areas. Picking is then controlled to use only as much of that capacity as is required for each batch. This approach still does not address the loss in sorter utilization resulting from these factors, as illustrated in Figure 5. (Note: In recent years, a dynamic wave planning logic, commonly referred to as “waveless,” has been used in some systems to address the start/end of wave losses in capacity and productivity).

Floating Zones

Alternatively, the control system for picking may shift capacity (people) between, or even during batches. One method for shifting capacity is illustrated in Figure 6. The pick path may be viewed as continuous. The length of path assigned to an operator will vary from batch to batch depending on the density of demand along the path, and even may be based on individual operators’ performance capability. This concept is known as a floating zone because each operator will be assigned a different set of continuous locations to pick from during each wave, but the amount of work that any given operator has at the start of the work is the same. By doing this, they work in the different zones complete at more or less the same time.

Multiple Forward Pick Locations

Another method of addressing zone imbalances is to provide picking locations for the most popular products in several zones. The control system can shift the source of these products from batch to batch(i.e. zone to zone) to help balance the workload. For example, imagine that an Item #123 is available in Zone A and Zone B within a warehouse. If during the wave planning phase, Zone A’s workload looks to be noticeably greater than Zone B’s, the system can shift all or some of the picks for Item #123 to Zone B.

ADDRESSING THE ISSUE OF SORTER UTILIZATION

In wave picking environments, cases will be flowing from each of the picking sub-systems and from several zones within some of these sub-systems at different rates. The sorter will run at a constant speed and when a low flow results in underutilization, that capacity is lost forever. So, if it is important to achieve high sorter utilization to satisfy the total demand, then the picking and conveying system, together, must maintain a steady flow of products. To do that, some method must be designed to accumulate and release cases within the system.

How Much Accumulation Should You Buy?

The merging of flows and the buffering of peaks and valleys in the instantaneous rates is a critical part of any wave picking system design. Figure 7 illustrates a combination of picking modes, all feeding into the same sorter. There are a variety of different ways and areas in which accumulation could take place. Of course, the ideal solution would be to provide conveyor lanes to accumulate all the cases from all picking areas for a single wave, and then to release it to the sorter at a constant rate. This is often a practical solution for the sortation of small items that can be accumulated with 10-20 pieces in a tote box. But, the conveyor length to hold a complete batch of full cases is usually prohibitively expensive. So, a trade-off of accumulation, control of picking, and sorter capacity must be evaluated.

Where Should Accumulation Take Place?

It would seem to make the most sense to put the accumulation as close as possible to the sorter so that it can be shared by all picking zones. However, in a large system, the distances from the various picking zones to the sorter could require that conveyors for transport also be used for accumulation. This solution may not be cheap; accumulation conveyor is much more expensive than the traditional motorized conveyor.

For the very high volume products that may be needed in full pallet quantities at the sorter or for the very slow-moving products that are batch picked to a pallet or roll cage to be inducted into the sorter, accumulation is easier. These products may be picked or retrieved from storage in advance of the batch for which they are needed and kept in pallet form until the time comes for their induction. This, of course, is not an option for pick-to-belt or pick car situations.

CHOOSING THE RIGHT SORTER

There are a number of sorter types to choose from for case sortation. Selecting the one that is most appropriate for a specific system depends on the sorting rate required and the handling characteristics of the products passing through. Regardless of which type of sorter is selected, many of the other design issues are similar.

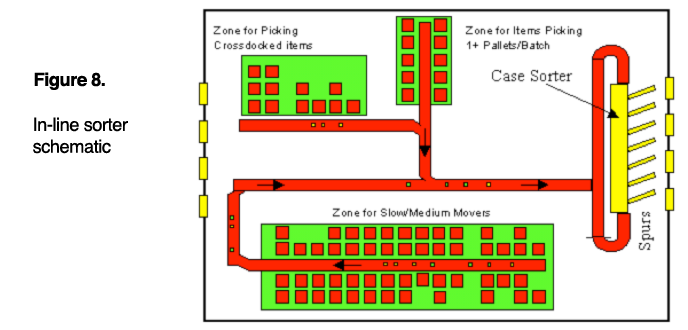

Figure 8 indicates an in-line sorter with a recirculation loop.

Within this simple configuration, a number of important trade-offs exist. They relate to:

- Number of Spurs

- Spur Length

- Recirculation

Number of Spurs

In general, a spur is assigned to each customer order in the wave, however, there are some reasons to create more, or even fewer than this number.

- Large orders, which may have very high flow rates at times during the sortation of the wave, may be assigned two or more spurs to provide some temporary accumulation or to permit more than one operator to palletize cases for that order at the same time.

- Additional spurs may be used to provide a separation of product families for each order. This may be traded-off against more sophisticated control of the picking process.

- Additional spurs may be provided to permit the overlapping of waves. Cartons arriving early for orders in the next batch may be assigned to a spur not utilized in the previous batch.

In some cases, fewer spurs may be provided if, for example, two small orders are sent to the same spur and manually separated during the palletizing process.

Spur Length

If there were always a loading operator available when a case arrived in a spur, the spur would need no accumulation capacity. But, because there are usually 5 to 10 spurs/operator, it makes sense for the operator to move from spur to spur when several cases have accumulated so that the walking time is reduced.

When a spur is full because the loader has not been able to service it, newly arriving cases cannot be diverted and must recirculate.

So, trade-offs exist here between spur length, the response time of servicing, the number of spurs assigned to an order, and utilization of sorter capacity for recirculation.

Recirculation

Cases that cannot be diverted on their first pass across the sorter may do one of three things. They may:

- Exit the sorter in a “dump” lane and be, manually moved to the end of the proper spur.

- Recirculate directly back to the sorter induct point.

- Divert into a separate recirculation/accumulation lane.

The first alternative is an easy solution if a company elects not to do the analysis to choose between alternatives #2 and #3; however, it should not be overused. On the other hand, it should not be overlooked as a solution for exceptional occurrences, when a mechanical solution might be quite expensive.

Alternative #2 is acceptable as long as there is sufficient sorter capacity to handle recirculation and accept new incoming cases. If there is insufficient capacity to do so, priority may be given to the new cases, but when the recirculation line fills, the system will slow down. Or, priority may be given to recirculation, slowing the rate of accepting new cases. This could, in turn, slow down the picking process. This is not desirable, but might be the best way to automatically adjust the system, so long as it it does not occur so often as to adversely affect picking productivity. The additional lane in alternative #3 may be used to hold cases that have arrived early and then release those cartons when spurs are available for them.

SUMMARY

In summary, when constructing higher volume case pick facilities, there is a number of questions to be answered in the design process.

- What picking methods are appropriate?

- How should products be assigned?

- to picking method

- to zones within each method

- How should picking be controlled?

- Where should accumulation be provided?

- At the sorter,

- How fast should the sorter be?

- How should recirculation be managed?

- How many spurs are required?

- How should orders be assigned to spurs’?

Of course, there are many more detailed design issues to address, but those mentioned here begin to illustrate the complexity of system design involved in making the “right” concept work effectively.

As of September 8, 2020, Crimson & Co (formerly The Progress Group/TPG) has rebranded as Argon & Co following the successful merger with Argon Consulting in April 2018.