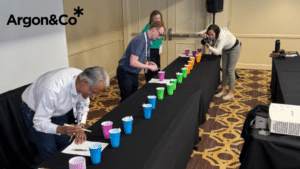

Our simulation in a WERC session of serial picking vs bucket brigade picking replicating a slower worker using chopsticks, a medium speed worker using pliers, and a fast picker at regular speed and analyzing live the productivity increase.

Exciting news emerged from this year’s WERC conference in New Orleans, where industry leaders gathered to share the latest innovations happening in the world in warehousing practice and technology. We were honored to take the stage and reveal a breakthrough: by transitioning from the traditional pick & passing method to the bucket brigade picking approach, we achieved a remarkable 40% increase in picking productivity.

WERC has always been dedicated to introducing fresh concepts to the North American warehousing community, and this year was no exception. Argon & Co’s Steve Mulaik, Rachel Patel, Brian Buckly along with client Rich Bushell with Stampin’ Up! were thrilled to present a case study featuring how Argon & Co helped our client significantly improved picking productivity. One challenge was that they already had a state-of-the-art solution.

Left to right: Steve Mulaik, Rachel Patel and Brian Buckley

The challenge: elevating Stampin’ Up!

Stampin’ Up! approached us with a clear challenge: their existing pick-to-light system was limiting their fulfillment potential. They needed a solution that would streamline operations, boost accuracy, and, most importantly, increase picking productivity.

Our Solution: WMS/WCS/voice-picking & bucket brigade picking method

After conducting a thorough assessment of the Stampin’ Up! warehouse operations, we recommended a comprehensive upgrade to their warehouse management and control systems (WMS/WCS), integrated with advanced voice-picking technology. But the real game-changer was the introduction of the bucket brigade picking method.

By replacing the traditional pick & pass process with bucket brigade, Argon & Co empowered Stampin’ Up!’s team to work more fluidly and efficiently. The results speak for themselves: a 20%+ boost in productivity.

“The Argon & Co team took our project to the next level. Rather than focusing on just replacing what we had, they guided us in a direction that helped to eliminate waste and improve overall the Order fulfillment process. Their approach to doing things is a game changer and was critical to help build the right solution that will move us forward into the next phase of our business. “ – Rich Bushell, Director of Global Distribution Services, Stampin’ Up!

Live demonstration: seeing is believing

To showcase the impact, we conducted two live picking simulations at the conference using attendee volunteers. The outcome was clear: bucket brigade picking delivered a 40% productivity increase over the pick & pass method. The demonstration provided compelling, hands-on validation of the method’s effectiveness for all to see.

How we can help your company achieve fulfillment excellence

We specialize in helping ecommerce and retail businesses like Stampin’ Up! transform their warehouse and fulfillment operations and WERC helped us teach others. Whether you’re looking to upgrade your technology stack, optimize your picking processes, or implement cutting-edge methods like bucket brigade, our team brings the expertise and experience needed to deliver measurable results.

Our services include:

Warehouse process assessment: We analyze your current operations to identify bottlenecks and improvement opportunities.

Technology selection & integration: From WMS/WCS to voice-picking and automation, we develop and drive implementations tailored to your specific needs.

Process innovation: We can lead you to designs that others can’t.

Ongoing support: Our partnership doesn’t end at implementation; we provide ongoing support and optimization to keep your operations ahead of the curve.

Contact us to schedule a consultation and see how we can help your business thrive. [email protected]

A project we featured at WERC 2024 was featured here in DC Velocity.